Perforated kinetic facade, also known as a wind chime facade, is composed of regularly arranged moving panels. The design principle of a wind chime facade is to simulate the effect of wind blowing using dynamic wind forces. Its structure is relatively simple, usually using stainless steel cables to link the metal moving panels, fixing one side of the panels and allowing movement only in one direction. This allows the wall to dance in the air with the wind, appearing light, agile, and flowing naturally. In the field of architecture, wind chime facades are mainly used for building facades, landscape walls, interior walls, etc.

Building facade

Landscape wall

Interior wall

The decorative effect of perforated kinetic facade is often related to material shape, material texture, size specifications, installation structure, and layout. Next, let's take a look at the relevant design points together!

Shape

With the improvement of technology, the shapes of perforated kinetic facades are becoming more and more diverse. Mainstream shapes on the market include: rectangle, triangle, hexagon, diamond, circle, irregular, etc. The shape of the perforated kinetic facades can be determined based on factors such as architectural design style, wind-driven effect, lighting design, construction technology, and cost.

Rectangular perforated kinetic panels

Triangular perforated kinetic panels

Hexagonal perforated kinetic panels

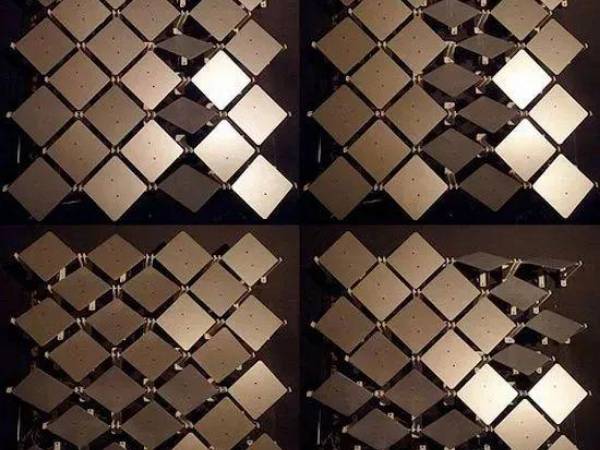

Rhombus perforated kinetic panels

Round perforated kinetic panels

Shaped metal perforated kinetic panels

Material

Metal materials are the most suitable for perforated kinetic facades. The strong reflectivity and unique metallic luster will make the perforated kinetic facades more stunning. Common metal materials include perforated kinetic stainless steel, aluminum, and copper, as well as non-metal materials such as PET, PC, and acrylic for selection. Clients can choose the right material based on design style, material performance, and cost. For example, if you want to use copper perforated kinetic facades, consider the cost when using them on a large scale.

Stainless steel perforated kinetic facade

Aluminium perforated kinetic facade

Copper perforated kinetic facade

Plated stainless steel perforated kinetic facade

Mirror aluminum perforated kinetic facade

Acrylic perforated kinetic panels

| No. | Material | Thickness | Price (RMB/m2) |

|---|---|---|---|

| 1 | Stainless steel | 0.6–1.0 mm | 2,500–3,000 |

| 2 | Aluminum plate | 0.8–3.5 mm | 100–250 |

| 3 | Copper | 0.6–3.5 mm | 2,800–4,000 |

| 4 | PET | 0.8 mm | 50–100 |

Layout Method

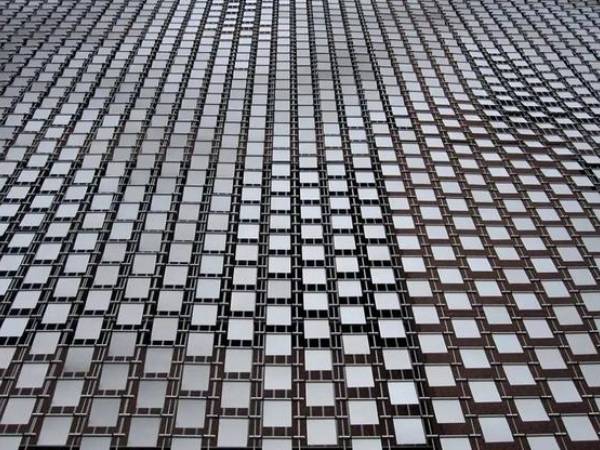

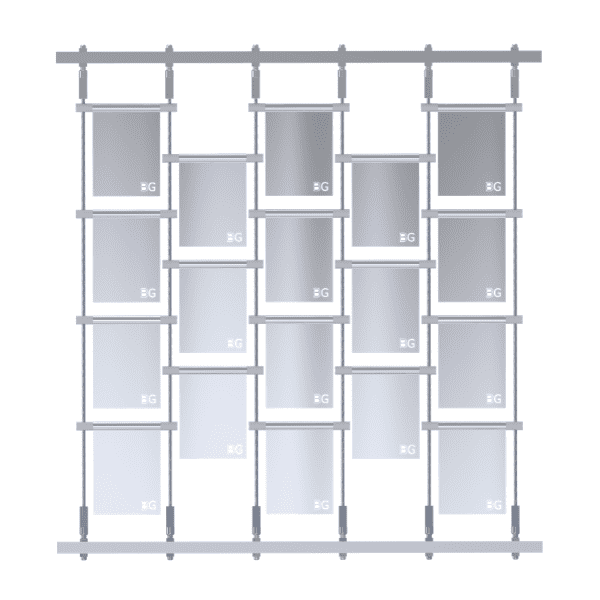

Among the commonly used wind-driven panel layout methods, they can generally be divided into parallel, staggered, overlapping, and hollow styles. The texture and moving effect produced will also vary greatly. You can also choose between horizontal and vertical moving directions.

In the selection of layout methods and moving directions, each panel on the facade is regular and uniform. To not affect the overall visual effect, usually only one type of layout is used and not two or more types.

Parallel perforated kinetic facade

Staggered perforated kinetic facade

Overlapping perforated kinetic facade

Hollow perforated kinetic panels

Horizontal movement perforated kinetic panels

Vertical movement perforated kinetic panels

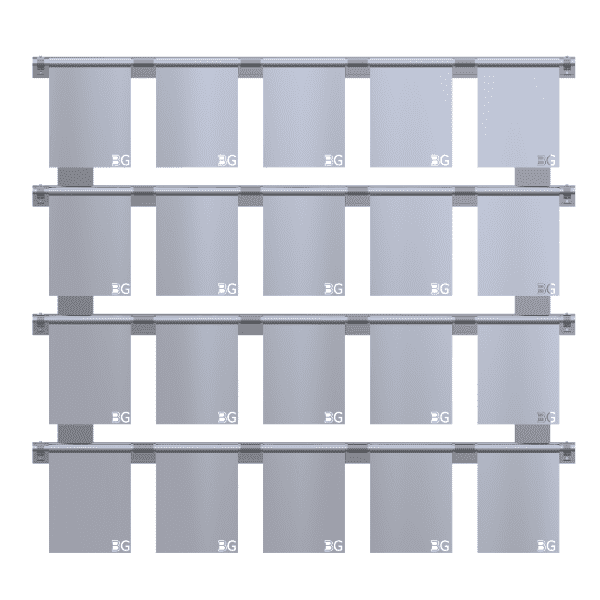

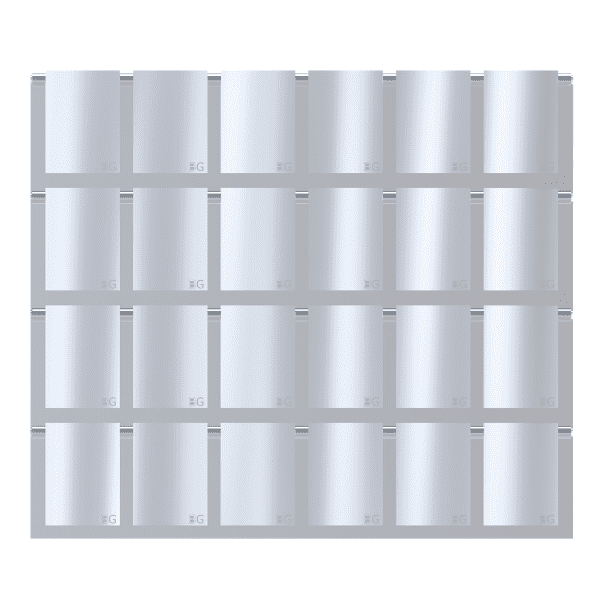

Types

The selection of installation structure mainly refers to the installation and fixing methods of perforated kinetic sheets (panels), accessories, and keels. There are usually keel mountings, back plate mountings, and hanging mountings. Clients can choose the mounting structure according to the desired kinetic effect.

Keel mounting

Back plate mounting

Hanging mounting

Installation Components

The installation of perforated kinetic facade includes wind moving piece, panel, hollow long tube, limit sleeve, convex part, vertical keel, insert core, sealing glue, connecting seat, through connecting bolt, connecting piece, erection plate, fixing piece, limit through tube, limit groove, fixing groove, gasket, etc.

Installation Steps

Before construction, we should make sure that the construction environment meets the standard requirements, check whether the construction materials are intact, whether the tools are well prepared, and whether the construction personnel do a good job of technical briefing.

According to the design drawings and on-site measurements, determine the installation size and position of the keel frame, fix it with the wall or curtain wall post through the connectors, and check whether the installation is safe and firm.

According to the design drawings and positioning points of the fasteners, the stainless steel cable will be installed and fixed to the keel frame with the cable fasteners.

The sleeve at the top of the kinetic panels is socketed on the mandrel, there are screws at both ends of the mandrel, and there is a steel cable hole at its root to ensure that the axis of the steel cable hole is perpendicular to the axis of the mandrel, and there is a fastening washer on the screw, and there is a fastening nut rotated at the outer end of the screw, and there is also a cover plate attached to the mandrel, and there is a bayonet at both ends of the cover plate, and the bayonet is installed in a position corresponding to the position of the steel cable hole.

After each installation of a kinetic panel, need to manually check its flexibility, the core and stainless steel cable is vertical, etc., to be fully installed after the completion of the construction site.

Installation material inspection

Frame and cable installation

Assembling and checking kinetic panels

Inquiry for Our Product

Boegger Industech Limited

E-mail:

info@perforated-sheet.com

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.