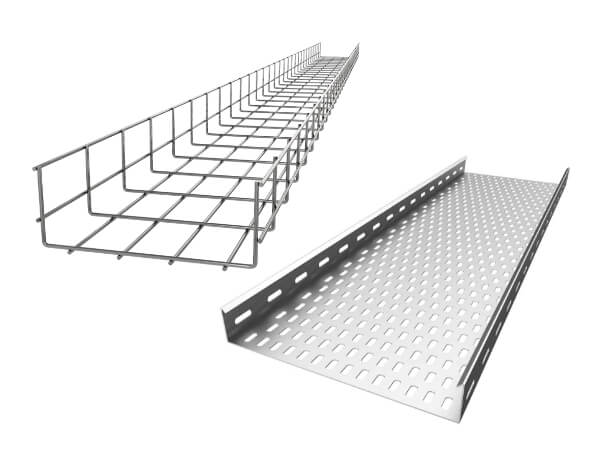

Cable trays are often divided into perforated cable trays and welded cable trays.

Perforated cable tray is a kind of cable tray with holes on the bottom sheet and side rails for the distribution of electricity, and signaling in industrial plants, department stores, gyms, hospitals, airports, and other industries.

Perforated cable trays provide excellent ventilation, enhance cable life, and can be attached to any structure. Its solid base allows the installation of a large number of heavy-duty power cables, providing stable support for the electrical system. In addition, aluminum perforated cable trays are lightweight, corrosion resistant, and aesthetically pleasing, making them an ideal cable management solution.

Welded cable trays are made up of a series of interconnected metal wires, which create a mesh-like structure that can be used to route cables and wires through a space. It is well-ventilated and easy to clean and maintain.

It is also known as a cable management tray, generally available in three types of installation: ceiling mountable, wall mountable, and floor mountable.

Features

Specification

| No. | Material | Wire Diameter | Hole Size | Size (H × W × L) |

|---|---|---|---|---|

| mm | mm | mm | ||

| 1 | SS304 | 4 | 50 × 100 | 55 (H) × 100 (W) × 3,000 (L) |

| 2 | SS304 | 4 | 50 × 100 | 55 (H) × 200 (W) × 3,000 (L) |

| 3 | SS304 | 4 | 50 × 100 | 55 (H) × 300 (W) × 3,000 (L) |

Products Display

Application Cases

Inquiry for Our Product

Boegger Industech Limited

E-mail:

info@perforated-sheet.com

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.