Nowadays, building materials are becoming more and more abundant and innovative, and a single material can no longer meet design needs. Would you like some original building materials? In fact, ordinary materials add some creativity, there will be unexpected surprises, such as perforated sheets.

Perforated sheet, as the name suggests, is a perforated metal plate, also known as perforated plate, perforated metal, perforated screen, etc., most of which is made of aluminum alloy metal plate, through the processing of stamping press or milling machine, with a long service life, not easy to deformation and other characteristics.

Perforated metal sheet has a history of nearly 150 years, initially developed as filter and sorter, mainly used in the mining industry. With the development of technology, its applications quickly expanded beyond its original function and have evolved to be widely used in architecture, landscaping, and interior design.

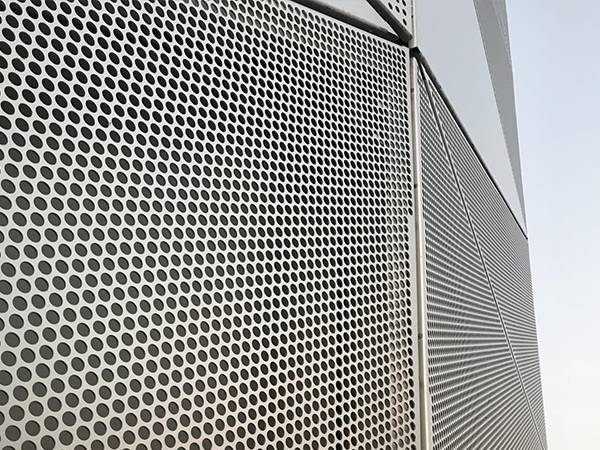

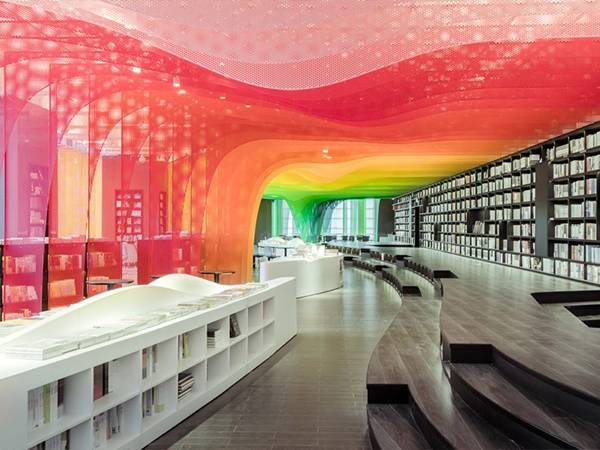

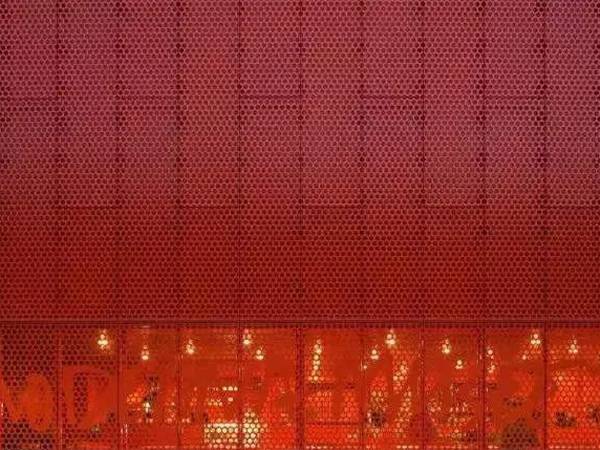

As a metal building material, perforated sheet is born with an avant-garde temperament, and is used in a large number of buildings, landscapes, and indoor and outdoor decorations to create a stylish and modern aesthetic. The hole size and pattern of the perforated sheet can be carefully processed and designed according to the needs, with different sizes, densities, and shapes of holes to form different translucent sight effects.

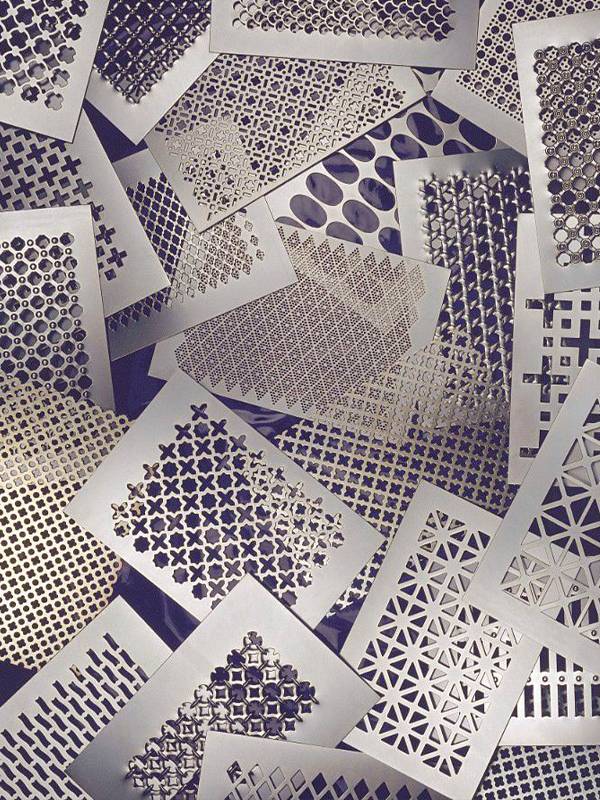

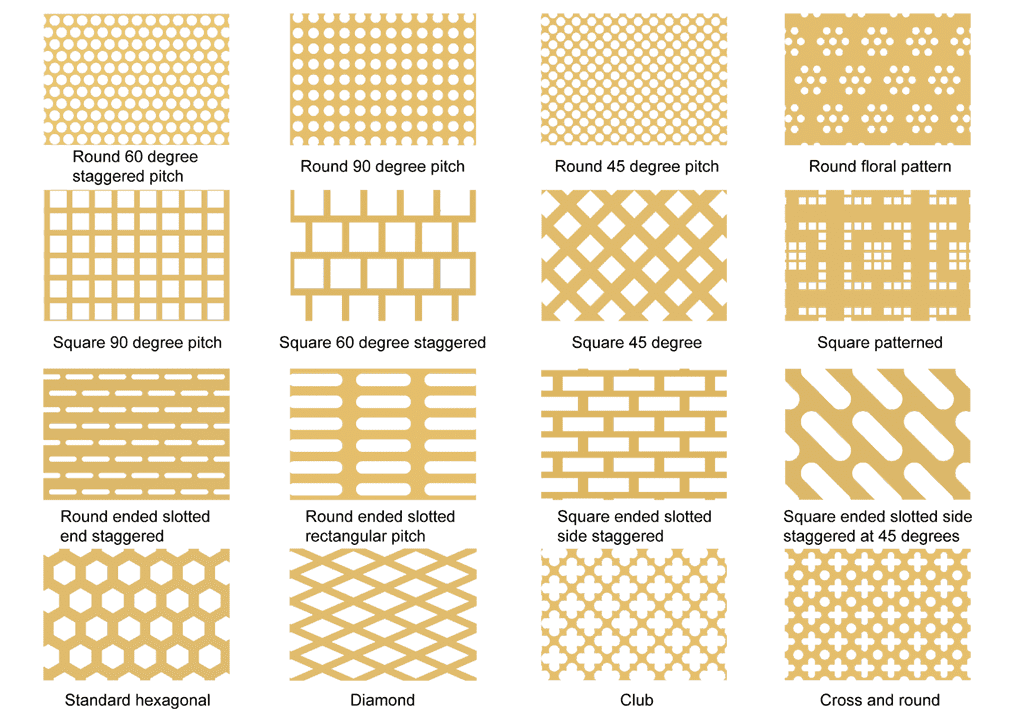

Decorative perforated sheet hole patterns:

rectangular, square, diamond, round, oblong, hexagonal, cross , triangular, kidney-shaped, flower, fishscale, pattern-design, octagonal, herringbone, five-pointed star shaped, irregular, bulge, heterotype, louver holes, and so on.

Perforated sheet materials:

The materials are mostly stainless steel sheets, aluminum sheets, iron sheets, copper sheets, etc. There are mostly perforated aluminum sheets on the current market, which are lightweight, beautiful in shape, elegant in color, easy to assemble, and have good chemical stability, a strong three-dimensional sense, and a good decorative effect.

Perforated sheet advantages:

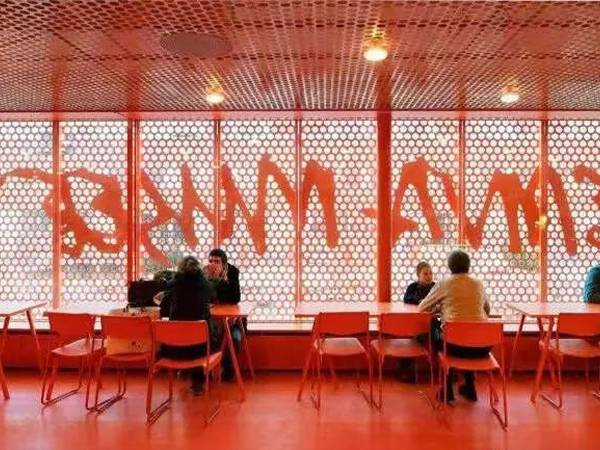

The most direct appearance of the perforated metal sheet is characterized by porousness, which means that the two parts of the space separated by the skin have permeability to each other, breaking the inherent boundaries between inside and outside, formally creating a more open public space, which can provide the city and the user with the intuitive feeling of the needs of the city and truly do the internal space and the external space of mutual permeability.

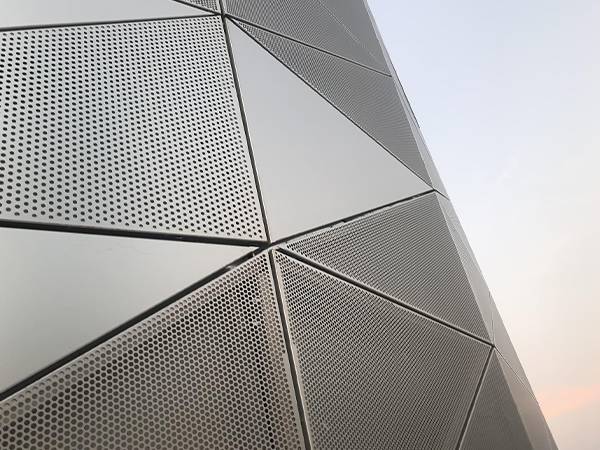

Perforated metal sheets can be made in different shapes and sizes according to the architect's needs. It is also possible to connect different perforated metal sheets in a variety of combination types.

In the field of acoustics, sound absorption is one of the most important measures for controlling noise and improving sound quality in the room. While perforated sheets have the ability to make it. Studies have shown that perforated metal sheets help reduce sound levels, that their acoustic properties help people minimize the health effects of noise, and that the use of perforated sheets in front of a building's facade can lead to energy savings of 29%. In the design process of concert halls, movie theaters, multi-purpose halls, etc., sound-absorbing structures are widely used as the main technical means of sound quality design and noise control.

Nowadays, perforated metal sheets have been used by designers in a variety of fields, from industrial filters and acoustic panels to architectural interior decoration, ceiling decoration, and backdrops.

Perforated Sheet Punching Machine

Perforated Sheet Laser Cutting

Perforated sheets can be used on building facades, separating space while achieving semi-privacy and security. The space still maintains comfortable air permeability and forms wonderful light and shadow effects. They can be combined with other building materials to form different senses of reality and texture so that the building facade gets a wealth of artistic changes.

Perforated sheets in the indoor field can be used as a space partition or decoration to create a low-key simple fashion style. The light through different holes, with the change of light and shadow, creates an extraordinary artistic effect.

Perforated sheets, both as a building material and play a very important role in interior decoration. With both value and strength, isn't such a perforated sheet very practical? If you are interested, you can contact us, and we will provide you with professional technical support.

Inquiry for Our Product

Boegger Industech Limited

E-mail:

info@perforated-sheet.com

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.