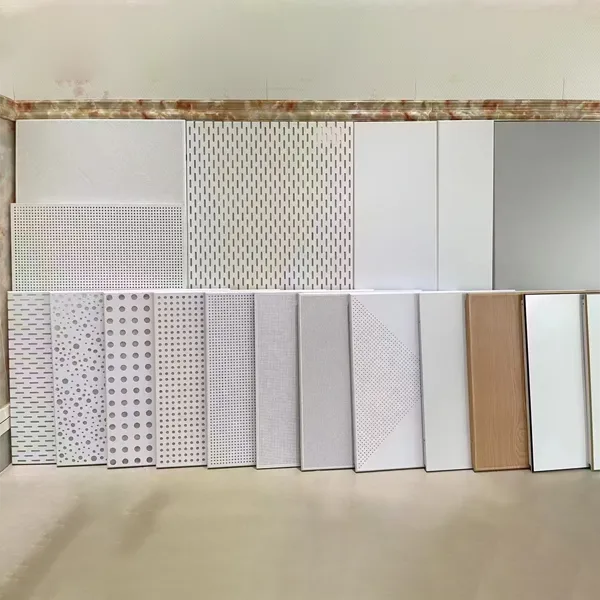

Perforated metal acoustic panels, also called perforated sheets, perforated panels, or perforated metal sheets, have become a sought-after choice for modern indoor acoustic ceilings, thanks to their seamless blend of functionality and aesthetics.

Our perforated ceiling systems, centered on these panels, offer excellent sound absorption alongside a sleek, modern look that complements diverse architectural designs. Precision-engineered, the panels control indoor sound reverberation effectively: sound waves pass through their precisely sized perforations, then are captured and absorbed by specialized backing materials. This drastically cuts ambient noise, boosts acoustic comfort, and enhances occupant experience.

Specifications

Benefits

Install

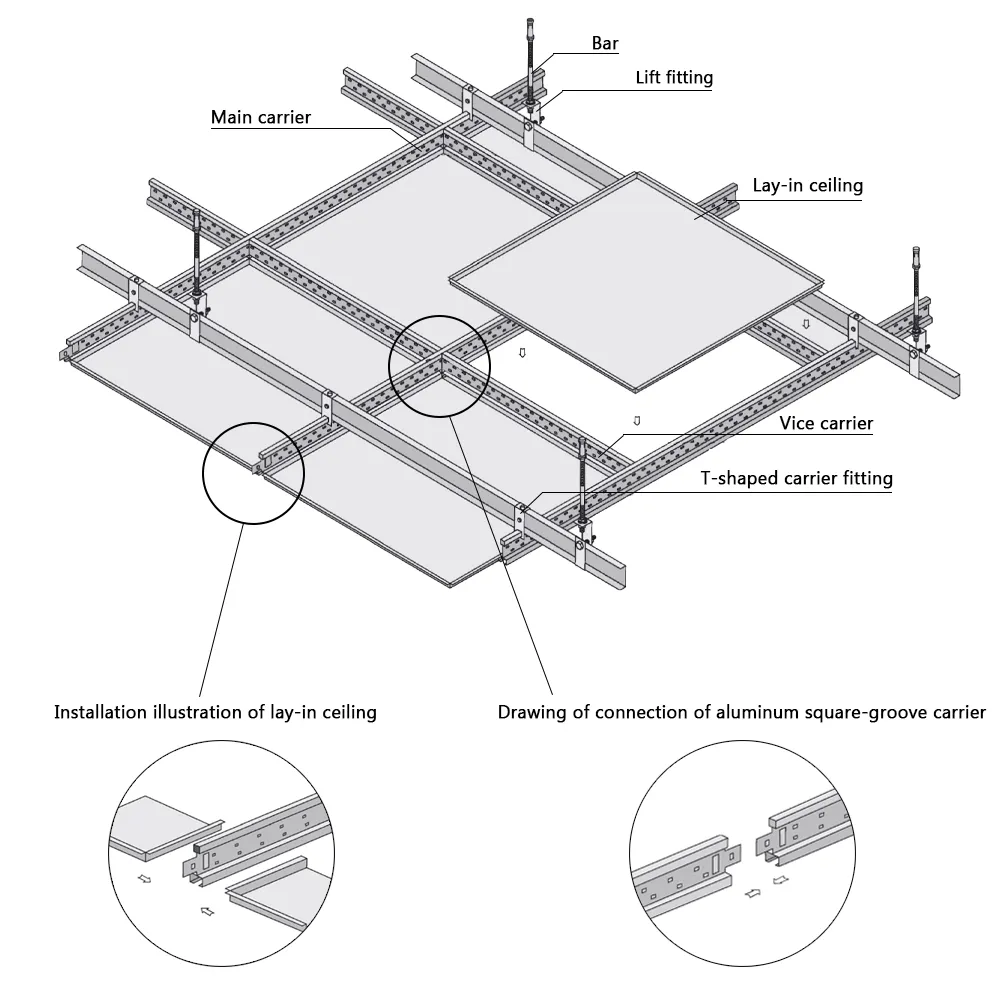

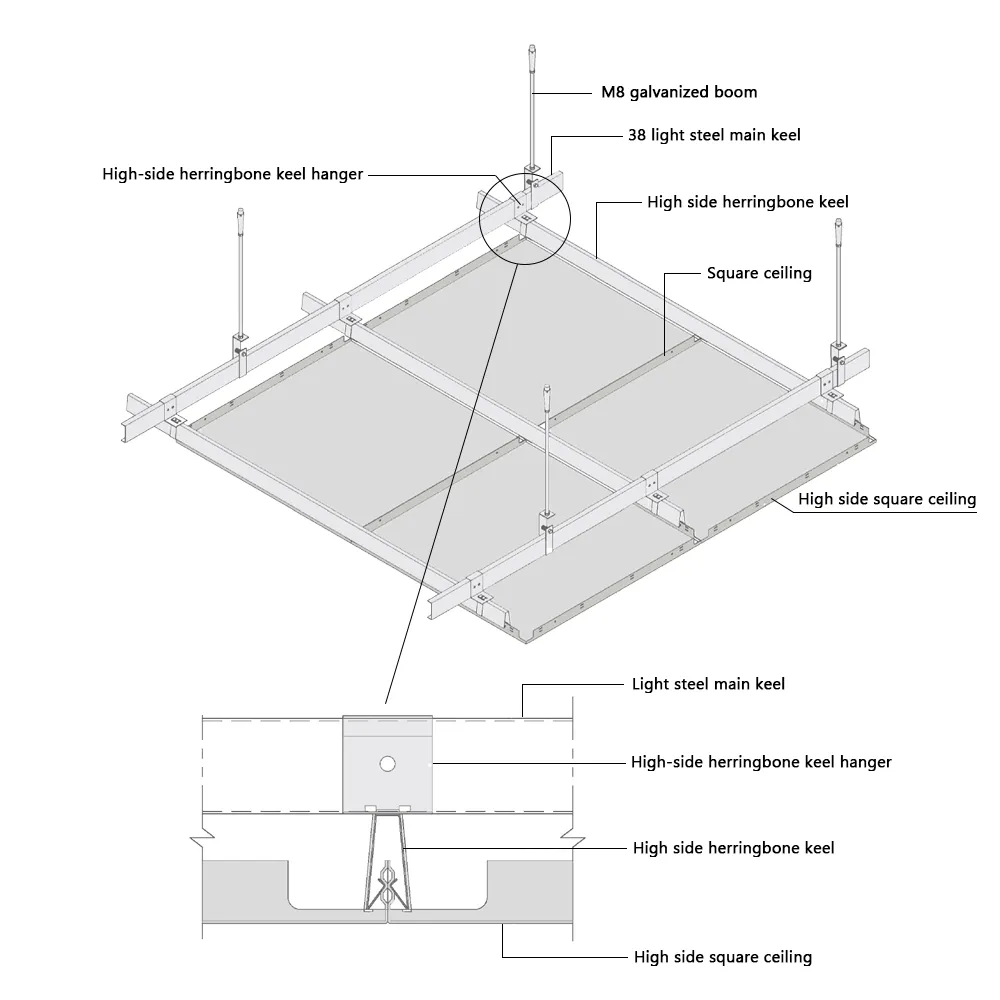

The exposed frame ceiling consists of decorative panels, exposed keels, upper light steel main keels, and supporting accessories. Featuring a flat panel surface and distinct edge lines, the ceiling system presents a neat, sophisticated and elegant appearance while offering an expansive visual effect.

Functionally, this exposed frame ceiling boasts excellent performance: it exhibits flame-retardant, anti-corrosive and moisture-resistant properties, and facilitates easy assembly and disassembly. A key advantage lies in its modular design – each panel supports independent installation and removal, which significantly simplifies construction, maintenance and cleaning processes.

It provides strong coverage for concealed installations (such as pipelines and structural components) in the ceiling, effectively hiding internal fixtures while guaranteeing the uniformity and aesthetics of the entire ceiling. Beyond this key benefit, the product features a seamless, flat surface, vivid designs, a wide range of colors and sizes, and long-lasting durability. Boasting exceptional quality paired with a noble and elegant appeal, it also delivers outstanding sound insulation performance, and can be flexibly used in combination with slats and square panels to suit diverse application needs.

Additionally, it offers a host of practical advantages: it is fire-resistant, moisture-proof, and corrosion-resistant, while being easy to clean. With a lightweight structure, it allows for convenient installation and disassembly. Notably, each panel is equipped with a dedicated positioning groove, ensuring smooth and flush installation.

Application

The product is widely used in office buildings, offices, airports, railway stations, factories, hospitals, clubs, banks, shopping malls, exhibition halls and so on.

Inquiry for Our Product

Boegger Industech Limited

E-mail:

info@perforated-sheet.com

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.